POS Printers

POS PRINTERS

3 main types used on our POS systems: LABEL, THERMAL, IMPACT

THERMAL: S80/TP100: also called receipt printers, uses special paper.

IMPACT: M300: also called Kitchen or Dot Matrix printers, use normal paper rolls but uses an ink ribbon.

LABEL: Zebra: Direct thermal (prints direct on label) and Thermal Transfer (resin/wax ribbon to print on waterproof labels / card shelf tags)

BASIC TROUBLESHOOTING / TESTING

1. Power on self-test: Hold the feed button and turn printer on, self-test should print.

Check for missing section of print / poor quality etc. Possible hardware / physical issue if self-test fails / poor quality.

2. Communication issues: Confirm connection method (serial, ethernet / USB / virtual COM via USB on TP100) confirm printer settings from self-test to POS settings and correct any differences.

network printers: ping IP address from command prompt. If responding, turn off and ping again, if still getting response possible IP address duplication.

serial / shared printers: printtest bat file.

serial port conflicts: multiple devices on same COM port (Linkly)

correct serial cable? TP100 and S80 use different cables.

3. Incorrect format / output: Check printer config on POS (baud rate, printer type etc.)

4. Print quality issues / jibberish output

Correct paper / tried a different roll?

thermal 80mm wide roll, can only print on one side, drag a fingernail across the paper and it should leave a black line, this side needs to face the printhead.

impact 76mm wide roll, can be 1 ,2, or 3 ply plain / bond paper.

Impact printers: ribbon not jammed (remove and turn dial to check), worn out (no ink left of fabric), correctly seated?

Correct printer type / comms settings configured in POS? Impact printers cannot print logos like the thermal printers so will get a large amount of jibberish print then the receipt.

5. Paper feed issues:

IMPACT: correct size roll, 76 mm

correct paper type (bond)

paper thickness (some printers don't support 3 ply, M300 does)

paper jam / jammed cutter (see model specific procedure)

angle of printer (mounting position can put extra pressure on a new roll which stops feeding)

THERMAL: correct size roll, 80 mm

correct paper type, thermal (fingernail test)

paper jam / jammed cutter (see model specific procedure)

Documents

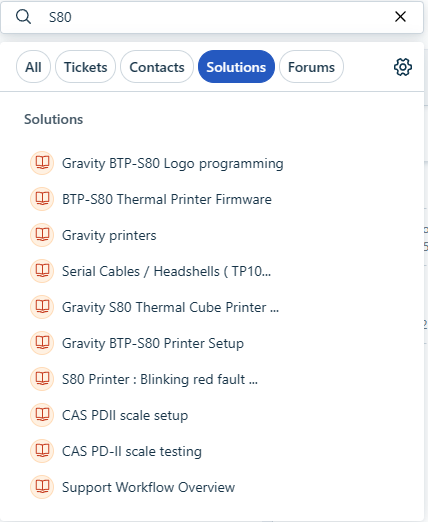

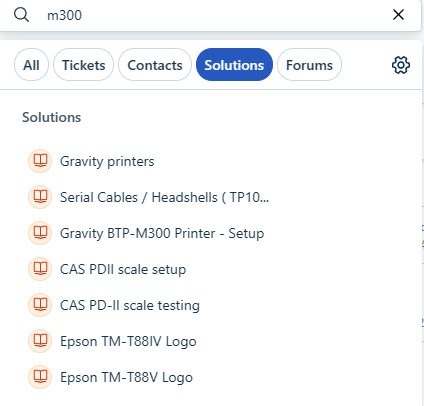

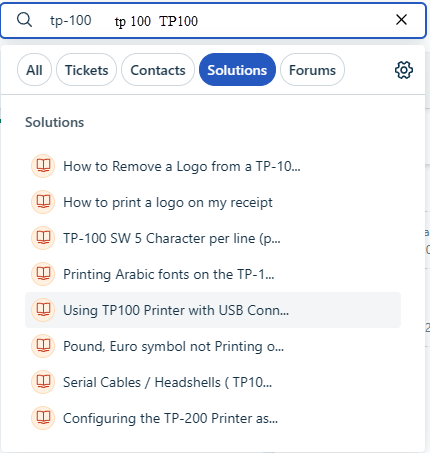

Search Idealpos Help Guides using the model id (S80, TP100, M300)